The inputs you need to have project risks under control throughout project lifetime.

Offshore Wind

and Onshore

Wind experts

RocBenergy has an extensive experience in the Wind energy industry, we are helping companies globally throughout the engineering and development, construction, and operation phases.

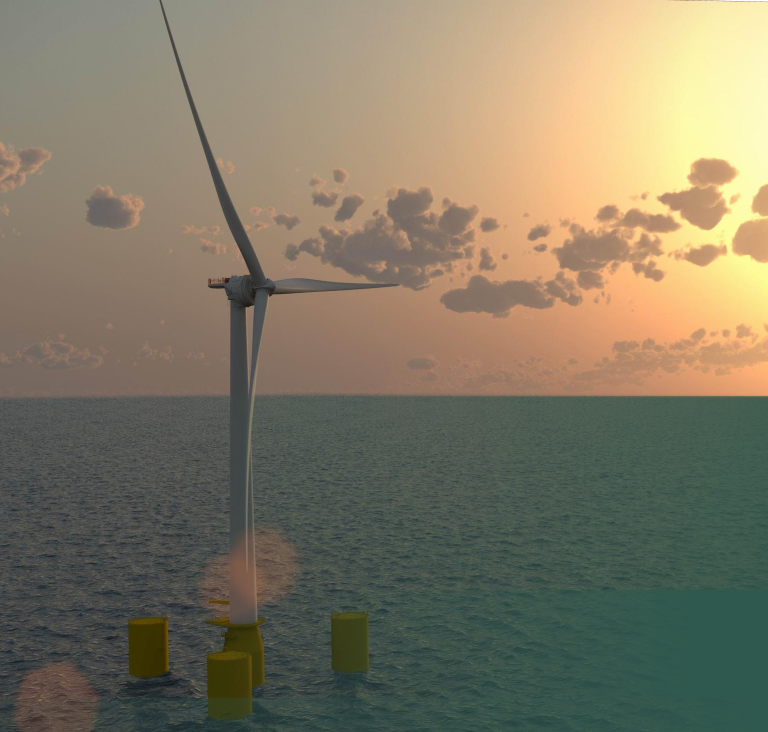

Offshore Wind

Floating Offshore

Onshore Wind

Our Services

With our extensive experience in the Wind energy industry, we are helping companies globally to ensure technical and commercial feasibility of their wind energy projects with a broad range of services: Technology, Product, Commercial, Logistics, O&M and Training.

01.Engineering and development

02.Construction

03. Operation

01.

Technology

We identify and propose the best technology for your project, including wind turbine and BoP components. We have a global reach so our supply chain investigations include usually equipment from any location where we find the best quality and cost.

We can start from the overall optimization of your windfarm, including all CAPEX and OPEX elements. We help you select the proper technologies for all windfarm components and we confirm that through the right assessments, including Technical Due Diligence of the proposed components and suppliers. We help managing the Engineering process to integrate all the different components into a final site specific design and certification.

Key points

Propose optimal technology.

Includes wind turbine and BoP components.

Global supply chain.

High-quality, cost-efficient.Wind farm optimization.

Select right technologies.

Technical Due Diligence.

Manage engineering process.

Site-specific design.

Final project certification.

Feasibility studies

WTG Technology assessment

Engineering management

01.Engineering and development

02.Construction

03. Operation

02.

Commercial

RocBenergy has a good understanding of the supply chain market for windfarms all over the world. Therefore we can study each case to propose the best solutions, wherever they come from.

We organize the procurement process, leading or contributing to your RFI/RFQ's, internal decision process and award.

We have a large experience setting up Contracts with suppliers: TSA, SMA, FEED, Early works agreements. We propose those contracts and negotiate with the suppliers to get the best conditions for you so that you avoid hidden risks that may become large over costs down the line of your project.

Key points

Understand global supply.

Study each case.

Propose best solutions.

Organize procurement process.

Lead RFI/RFQ processes.

Support internal decisions.

Award contracts efficiently.

Extensive contract experience.

Negotiate with suppliers.

Avoid hidden risks.

Market Survey

WTG Procurement

Contracts (TSA, SMA, FEED, Early works, and more)

01.Engineering and development

02.Construction

03. Operation

03.

Product Management

Our team has had relevant Product Management and Engineering positions in large Turbine OEM's. Therefore we are in a unic position to understand the market. We can help you benchmarking your alternative solutions, creating the right models to compare them and help in your product or features selection process.

We can advice you on your product validation process, whether it is a single turbine floating demo project or a large windfarm where a Project certificate needs to be implemented.

We will propose a plan to make sure that the technology you have selected is performing as expected (Power curve, loads, availability, etc.) so that the revenues in your project become a reality as planned.

Key points

Benchmark alternative solutions.

Create comparison models.

Assist feature selection.

Product validation advice.

Support floating windfarm and demo projects.

Ensure project certification.

Technology performance assurance.

Maximize project revenues.

Competitive Intelligence

Product Management

Product Validation

01.Engineering and development

02.Construction

03. Operation

04.

Logistics and Installation Engineering

We count with hands on experienced team when it comes to transport and install wind turbines. Former members of a reputated Offshore Wind OEM, our team is advising our customers in the preparation and engineering of their Offshore Wind projects. We can design and optimize your processes to the engineering detail that your project requires, including the design, sourcing and procurement of special tools.

RocBenergy is as well helping the Ports to be ready for Offshore Wind (Floating and fixed), identifying their potential market, defining the strategy and proposing the best layout alternatives for the different scenarios of their Offshore Wind offering.

With our large experience in Wind we can help planning the costs of your Transport and Installation processes.

We can as well help you in the sourcing and procurement process of those services and equipment (tools).

Key points

Experienced, hands-on team.

Offshore Wind expertise.

Process optimization services.

Special tools design.

Ports market strategy.

Best layout alternatives.

Wind cost planning.

Sourcing and procurement.

Equipment procurement assistance.

Installation process guidance.

Transport and Installation engineering

Port and logistics assessments

Transport and Installation cost assessment

01.Engineering and development

03.Operation

02.Construction

05.

O&M Engineering

We define the best strategies for each case so that your O&M is optimized for your project. We can go to the engineering detail as deeply as you may require, developing procedures and creating documentation for preventive and corrective maintenance including major component exchange, and decommissioning activities to provide clear instructions to technicians.

Our large, hands on experience allows us to identify all the elements involved in the different O&M processes and estimate their cost beforehand, so that your project cost planning is accurate to the level you expect.

We can as well develop or find custom tools with our tooling manufacturing partners to increase your capabilities, improve safety, and/or improve efficiency. Examples include reaction arms, fixtures, lifting devices, and site stands.

Key points

Optimized O&M strategies.

Detailed engineering procedures.

Preventive maintenance documentation.

Corrective maintenance plans.

Technician instruction clarity.

O&M process identification.

Accurate cost estimation.

Custom tooling solutions.

Safety and efficiency.

Improved project capabilities.

O&M Strategy and detailed engineering

O&M cost assessment

Custom tool design

01.Engineering and development

02.Construction

03.Operation

06.

Training

We deliver taylor made training, specifically designed for your company needs. Our extensive know-how about the topics we cover in our services, allows us to build training programs containing the elements that your team need in order to go a step beyond in your projects. We deliver those in house in your company for a better and more profitable learning experience.

As an example, a typical agenda for an Offshore training may look like this:

· WTG technology.

· Foundation technology: fixed and floating.

· BoP, offshore logistics, other elements.

· Project planning: development, FEED, procurement, construction.

· FEED typical contents and schedule

-Project specific engineering process: WTG/foundation integration, ILA, SKS & IAC.

· Transport, Installation and commissioning: strategies, risk allocation, innovations.

· O&M: strategies, risk allocation, innovations.

· Contractual setup (TSA and SMA)

Key points

Tailor made Offshore and Onshore training.

Hands on experienced teachers’ team.

In company delivery

Offshore technology

Onshore Technology

Commercial and Contractual elements